PCMR (Pty) Ltd

Power Cell Micro Reactor

Technology

The approach to develop the concept is to initially focus on the physics-engineering design of the AMR with the objective to maximize its local content in terms of the acquisition of components and the utilization of existing research facilities.

The technical configuration is chosen to maximise the use of technology systems, structures and components that have been developed, qualified, and used extensively in practical applications currently, and as such are available “off-the-shelf”. The only unique part of the system is the AMR reactor with its associated heat exchanger.

The conceptual design of the AMR has been completed and shows promise to fulfil at least three of the four high-level requirements as specified by the Generation IV International Forum (GIF) for future reactors. The three requirements are: enhanced safety, minimization of radioactive waste and to improve the resistance against nuclear explosive proliferation. The one GIF requirement that cannot be evaluated at this early stage is to show that the concept will be economical and that it is sustainable in future.

The results of the work that has been completed thus far show that during all the anticipated operational and upset conditions the core structures and fuel temperatures remain below their specified maximum values with only passive means of heat removal from the core and core structures. At this early stage of the analysis and development it can be concluded that to bring the concept to fruition very exciting research and development will have to follow and that this will very positively stimulate the revitalisation of the dormant capabilities still available in the country in the theoretical and practical fields of nuclear engineering science.

Looking somewhat further into the future it is easily recognised that the configuration of the Power Cell lends itself ideally to provide energy to a desalination facility incorporated into the final heat sink part of the system and that it can provide the possibility to co-generate process heat at 750ºC to 800ºC.

Reactor

The design objectives adopted for the reactor have been taken from the guidelines developed by the Generation IV International Forum (GIF) with major focus on the enhanced safety, minimised waste production and proliferation resistance features, while its incorporation in a Power Cell configuration addresses the sustainability dimension.

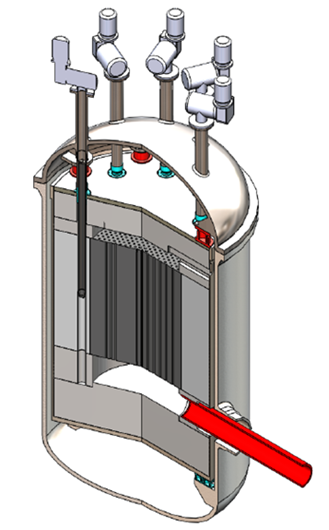

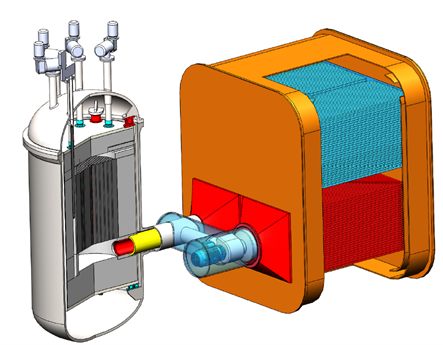

The reactor is a high temperature helium-gas cooled reactor. The helium coolant is circulated through the reactor core by an electric blower located close to the heat exchanger. As is custom for thermal neutron-spectrum high temperature reactors, graphite is used as moderator, which in this design, is in the form of a mono-block cylindrical configuration with a diameter of slightly more than 1 m and a height of a little less than 2 m. The fuel assemblies are silicon carbide tubes that contain the fuel as coated particles immersed in a Lead Bismuth Eutectic alloy in a Silicon Carbide tube. The fuel assemblies are evenly spaced lengthwise in the mono-block graphite structure, with an annulus around each for cooling by helium entering the core at the top. A graphite neutron reflector surrounds the core on the sides, top and bottom. The reactivity control of the core is by means of control rods located in the side-reflector.

The Power Cell configuration

Heat Exchanger

The heat produced by the reactor is exchanged to air circulated on the secondary side in a natural-convection Heat Pipe Heat Exchanger (HPHE). The coupled system is known as “the nuclear heat supply system” (NHSS). An image of the reactor and heat exchanger system combination is shown in the figure on the right.

Safety, Safeguards and Nuclear waste

Safety features

Fuel particles with silicon carbide as coating provide the first barrier against release of fission products. The silicon carbide wall of the fuel assembly provides the secondary barrier and the coolant pressure boundary the tertiary barrier.

On failure of the cooling system due to a complete loss of the cooling medium (helium inventory), the heat generation in the core from the decay of the built-up fission products will be removed by natural conduction and thermal radiation to the environment; in such an event the maximum fuel temperature will remain well within the maximum safe value.

On a slight heat-up of the core due to a slight disruption of the core cooling, the reactor will shut down due to its negative temperature coefficient of reactivity.

Helium is normally seen as an inert cooling-medium, but it contains a small percentage of an isotope that can be transmuted by neutron capture to tritium. Tritium diffuses relatively readily through metal barriers. The reactor cooling system and HPHE in this system provides two barriers against such diffusion and therefore will make the probability of tritium reaching the environment insignificantly small.

Safeguards features

The fuel is in the form of coated particles that are difficult to reprocess.

The fuel is low-enriched uranium with a high burn-up which will result in the production of plutonium that is not attractive to produce nuclear explosives.

The Republic of South Africa is a Member State who is party to the Nuclear Non-Proliferation Treaty (NPT) and has the obligation to declare relevant Nuclear Fuel Cycle and other related information under the provisions of the NPT, Comprehensive Safeguards Agreement and Additional Protocol Agreement, to the International Atomic Energy Agency (IAEA). These requirements have been legislated in National Government Legislation and falls within the ambit of the Department of Mineral Resources and Energy (DMRE). This function has subsequently been delegated to the South African Nuclear Energy Corporation SOC Ltd (Necsa).

Nuclear waste features

The high burn-up achieved in the fuel and the compact nature of the fuel assemblies (only the silicon carbide rods compactly filled with coated particles and filler material) provides the least volume of spent fuel assembly per unit of energy produced.

The fission products, that represent the very largest component of the radioactivity produced during operation of the reactor, is contained within two barriers in between this radioactivity and the environment. These barriers are the silicon carbide around the fuel kernel as the first, and the silicon carbide of the fuel tube the second.

This structural material of the fuel assembly (mainly the silicon carbide) is of such nature that it will be stable in an underground repository for millennia.

The reactor is designed to be transportable by low-bed truck to the location of the Power Cell. Fuel will be loaded at an accredited and licensed nuclear operator such as Necsa and sealed prior to shipment.

When a fuel reload is necessary, the reactor will be transported back to Necsa where the seals will be broken and the fuel unloaded before reloading of new fuel, once again sealed, and transported back to the site of operation. This fuel-loading/unloading concept will provide enhanced continuity of knowledge during the pre-operational-, operational-, and post-operational period of the fuel inventory associated with the reactor.